At Morse Air Systems we are constantly coming across power problems brought to us by our customers. Here are a few of them to show not only the sorts of problems that can arise but what can be done to solve them.

Firstly a quick word about power – in Australia we have a standard 240V single phase, or 415V three phase power, at 50Hz. Other countries however may have something different. For example the USA and Canada all operate on 60Hz. This has an effect on what speed a motor will run at- and if the motor is connected to your fan of course a different fan performance will be affected.

So what can Morse Air Systems do about this and other power problems. Firstly in the case of one customer who had limited power availability, we were able to downsize the motor, optimize the design so as not to overload his switchboard capacity.

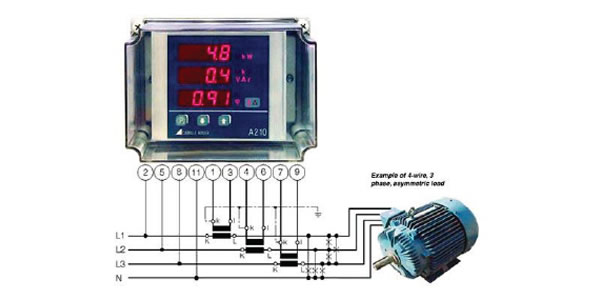

Other customers have required some variation in fan performance -Variable Speed Drives (VSD) are a great way to quickly alter your fans performance- and these are readily available, but need to be matched to the motor capacity. For small motors it is possible to use a 240V single phase input to obtain a 240V 3phase output, which for one customer was important as he did not want the expense of bringing in 3phase power. MAS has a close association with several motor companies that can supply VSDs and technical back up if required.

While talking about power, it is worth mentioning that in the case of belt drive fans that pulley sizes can be changed to alter the fan speed, but care must be taken (always consult with the Manufacturer!) that when speeding up a fan that you do not overload the motor. All the above issues highlight the major issue of specifying the required volume and pressure requirements up front, and if there is some doubt to talk to the experienced personnel at Morse Air Systems as we can offer advice or assist with system design – not just fan design.