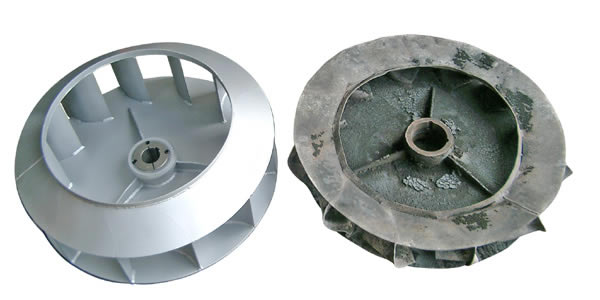

Picture above: our replacement along side the damaged version. Interesting talking point but not much good for moving air.

Recently “A” customer, who shall remain nameless, and who runs a large manufacturing concern had to meet a very critical chronological & geographic requirement (he had to be at a cricket match & was running late). As a direct result the furnace was shut down using the non-preferred methodology (he hit the emergency stop). Unfortunately this stops everything (including the fan) the resultant residual heat which normally is dispersed by the fan, wasn’t . Result an impeller which looks like above.

Morse Air Systems were quick to respond and had a replacement impeller built in a matter of days. Not bad when you consider that the impeller had to be identified, drawn up, laser cut, fabricated, fully balanced, and surface coated before being handed back to the customer.

We are able to offer this service as we have direct control over all aspects of the job and tremendous back up service from our suppliers. In addition, we have over the years built up an extensive library of designs including those from other companies which no longer exist. This helps us to verify the designs and performance and to get the customer back up and running.

At Morse Air Systems we understand that the fan is quite often the out of sight, out of mind piece of equipment- until it stops working. We are able to respond quickly to emergency requirements for replacement parts no matter what make or model, we can reproduce or provide a direct equivalent to your existing fan. We take breakdowns seriously, and you can be sure your breakdown will be given our highest priority.