Computational Fluid Dynamics (CFD) is the use of mathematics, physics and computational software to visualise how fluid flows. It also looks at how the fluid affects objects as it flows past. The analysis can be very complex— CFD is based on the Navier-Stokes equations; these equations describe how the velocity, pressure, temperature, and density of a moving fluid are related.

The ability to quantitatively predict the impact of such flows on product performance is critical to design success

.Morse Air Systems were contracted to investigate an impeller that had been troubled in recent times with near catastrophic failures; which could not be prevented or adequately explained. The impeller and shaft in question were examined; of note was the observation that the impeller had a very distinct and pronounced resonance.

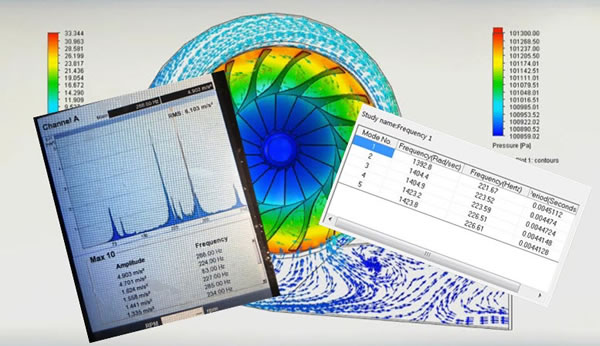

Using our Schenck Vibroport equipment, a Bump (also known as a Knock or Bong) test was performed. This test consists of hitting the impeller & recording the frequency response.

Through the results collected we could analyse the impeller design. We looked at the theoretical value of natural frequency using a Finite Element Analysis (FEA) model. Our FEA CFD model provided an insight into flow patterns that were difficult, expensive or impossible to study using traditional (experimental) techniques.

After comparing the results, a very close correlation between our FEA model and the actual recorded results were found. Our FEA model allowed us to be confident that a redesigned impeller would match and correct performance.

For more information on Morse Air Systems CFD analytical capabilities, contact us to speak with one of our experienced engineers.