These days noise is an important environmental and OH&S issue. For the most part when dealing with fans it is the “rush” or roar at an inlet or outlet that is the problem. If noise is an issue for you then please talk to us about this when discussing your fan requirements, as there are some design parameters that can be changed to give better noise results.

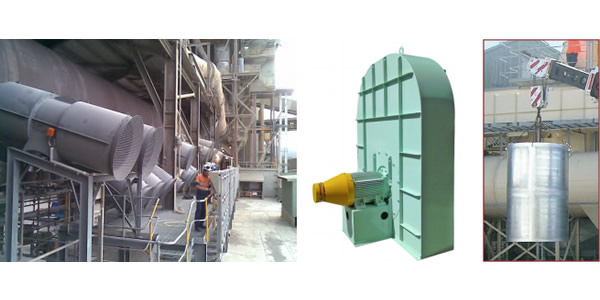

Morse Air Systems has many years of experience in designing and fabricating silencers to suit many applications. Here are a few examples:

- Silencers from Stainless Steels or Galvanised Steel to suit aggressive environments.

- Silencers with encapsulated Rockwool for moist/damp airstreams.

- Silencers that are able to be easily dismantled to change the Rockwool for very dusty air streams.

We can also increase the casing thickness or lag and clad the fan to reduce the casing breakout noise.

We can predict the amount of noise damping we are able to achieve and have noise level meters to enable us to check before & after noise levels – particularly useful if you want to retrofit a silencer. This is exactly what we did for a prominent lock manufacturer recently. They are located on the border of an industrial/residential area and running a 24 hour operation found that their late night noise emissions were excessive. Over the recent Christmas shutdown Morse Air Systems, installed 2 large silencers on the fan discharge dramatically cutting the noise produced. In fact the noise reduction achieved was exactly what we had calculated it would be. Customer was very happy (especially as this had been a last minute Christmas Shutdown addition) and the local residents are happy.

When dealing with larger motors then the noise problem may in fact be the motor itself and of course Morse Low Noise Fans has a variety of retrofittable cowls and cooling impellers which dramatically cut the motor noise (6-9dbA). In some cases we have achieved significantly more than this even!