Over the past few years Morse Air Systems have worked hard at developing a high performance onsite team. The focus has been on building up a range of skills and expertise that will benefit our customers on site.

Our mechanical and electrical skill set, plus the relevant onsite training, have enabled us to effectively deal with a range of projects. Following are just a few recent examples:

- Fan bearing replacements for hospital ventilation fans

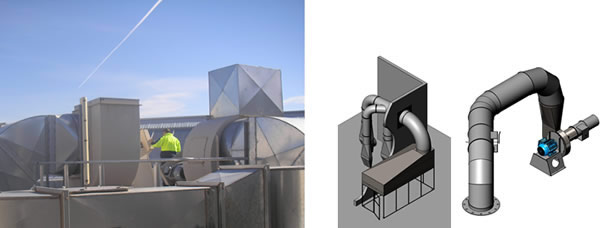

- Roof exhaust fan installation project in a new factory complex

- Car park fan refurbish works for a 25 year old city hotel

- Installation of fume exhaust system on a plastics process line

- On site balancing of a large fan impeller in a ventilation stack

Most projects require a certain level of engineering and design as well as co-ordination between other trades and services and of course the end user. Our extensive experience in project management linked with our qualified onsite team has resulted in projects being delivered safely and effectively.

“We control the project… we manage the risk…… we deliver the results”

With our inhouse engineering and fabrication capabilities along with our strong alliances with other equipment and service providers, we are able to react quickly to achieve tight schedules and quick turn-arounds.

If you require one of our company representatives to provide further details or to meet with you onsite please contact our office. With over 45 years in the industrial fan and systems industry we are confident that we can partner with you to deliver the desired results.